Hood to radiator seal

Hood to cowl seal

Other applications:

Edge seals

WS & BL edge seals

Trunk seal

Roof seal

Body mounted door seals

Body mounted door seals

Door mounted door seals

Door mounted door seals

Margin seals

Margin seals

Applications in the automotive industry

We are proud of being able to equip the whole vehicle with dynamic sealings. Our products have seven main applications in the automotive industry

Sealing-profiles

Self-adhesive profiles

Materials:

Materials:

- dense and/or cellular EPDM;.

- heat activatable or pressure sensitive acrylic foam tape.

Assembly:

- seal glued on customer interface

Optional features:

- drilled bulb holes

- coating (anti-friction, anti-UV,etc..)

- glass fiber wire

- flock tape stripes

Main applications:

- door seals – glass door seals – cabin windows seals – roof seals”

Snap-on top bulb profiles

Materials:

Materials:

- dense and/or cellular EPDM

- metal carrier / wire carrier

Assembly:

- Profile snap-on fixed on customer flange

Optional features:

- drilled bulb holes

- coating (anti-friction, anti-UV,etc..)

- sealant inside the snap-on

- metal carrier breakage

- glass fiber wire

Main applications:

- Trunk seal – roof seal – industrial application

Snap-on side bulb profiles

Materials:

Materials:

- dense and/or cellular EPDM

- metal carrier / wire carrier

Assembly:

- Profile snap-on fixed on customer flange

Optional features:

- drilled bulb holes

- coating (anti-friction, anti-UV,etc..)

- sealant inside the snap-on

- metal carrier breakage

- glass fiber wire

Main applications:

- Door seal – window seal

Snap-on top/side lip profile

Materials:

Materials:

- dense and/or cellular EPDM

- metal carrier / wire carrier

Assembly:

- Profile snap-on fixed on customer flange

Optional features:

- drilled bulb holes

- coating (anti-friction, anti-UV,etc..)

- sealant inside the snap-on

- metal carrier breakage

- glass fiber wire

Main applications:

- Engine hood seal – industrial application

Snap-on edge protector profiles

Materials:

Materials:

- dense EPDM or PVC

- metal carrier / wire carrier

Assembly:

- snap-on fixed on customer flange

Optional features:

- metal carrier breakage

Main applications:

- Sharp edges (to protect electrical cables, tubes that are in contact with sharp edges)

Glass run-channel profiles

Materials:

Materials:

- dense EPDM

- texturized coating

Assembly:

- pushed inside customer interface channel

Optional features:

- flock tape stripes

- glass fiber wire

Main applications:

- Sliding window seals (recreation vehicle, etc..)

Other profiles

Pushed-in profiles – mono-compound profiles – colour compounds – etc.

Pushed-in profiles – mono-compound profiles – colour compounds – etc.

Materials:

- dense and/or cellular EPDM

Assembly:

- pushed / clipped inside customer interface channel

Optional features:

- drilled bulb holes

- coating (anti-friction, anti-UV,etc.)

- glass fiber wire

Main applications:

- Roof seals, window seals, door seal

Our high-runner

The high runners are profiles which are produced at regular intervals. We produce profiles of compact and cellular rubber + tape – depending on the needs of our customers. Thanks to our technologies, we can adapt our production, depending on the profile requested.

Our inhouse tool shop allows us to create new dies for our customers.

High Runners

|

Bulb: Cellular rubber Base: Compact rubber Tape | 8875 | |

|

Bulb: Cellular rubber

Base: Compact rubber Tape |

8515 | |

|

Bulb: Cellular rubber

Base: Compact rubber Tape |

8656 | |

|

Cellular rubber Tape | 8592 | |

|

0.7-1.5 mm | Gripper: Compact rubber Bulb: Cellular rubber

Wire carrier |

8685 |

|

1.5-3 mm | Gripper: Compact rubber Bulb: Cellular rubber

Wire carrier |

8640 |

|

3-6 mm | Gripper: Compact rubber Bulb: Cellular rubber Metallic insert | 8613 |

|

3-6 mm | Gripper: Compact rubber Bulb: Cellular rubber Metallic insert

Sealant |

8916 |

|

1.5-2.5 mm | Gripper: Compact rubber Bulb: Cellular rubber Metallic insert | 8587-

00M001 |

|

5-6 mm | Gripper: Compact rubber Bulb: Cellular rubber Metallic insert | 8526-

00M001 |

|

5-6 mm | Gripper: Compact rubber Bulb: Cellular rubber Metallic insert | 8767 |

|

5-6 mm | Gripper: Compact rubber

Bulb: Cellular rubber Metallic insert Sealant |

8899-

00MM05 |

|

1-3 mm | Gripper: Compact rubber Lip: Cellular rubber

Metallic insert |

8538-

00M005 |

|

Gripper: compact rubber

Bulb: cellular rubber |

9384 | |

|

1-3 mm | Gripper: Compact rubber Metallic insert | 8664 |

|

2-4 mm | Gripper: Compact rubber Metallic insert | 8582-

04M001 |

|

1-2 mm | Gripper: Compact rubber Bulb: Cellular rubber Metallic insert | 8847 |

|

2.5-3.5 | Gripper: Compact rubber Lip: Cellular rubber

Wire carrier |

9378 |

|

5-6 mm | Gripper: Compact rubber Bulb: Cellular rubber

Lip: Cellular rubber Metallic insert |

8960 |

|

Compact rubber Coating | 9290 | |

|

5-6 mm | Gripper: Compact rubber Bulb: Cellular rubber Metallic insert | 9069 |

|

2-2.5mm | Waist belt seal with structurized coating | 9391 |

|

self adhesive cable channel seal | 9382 | |

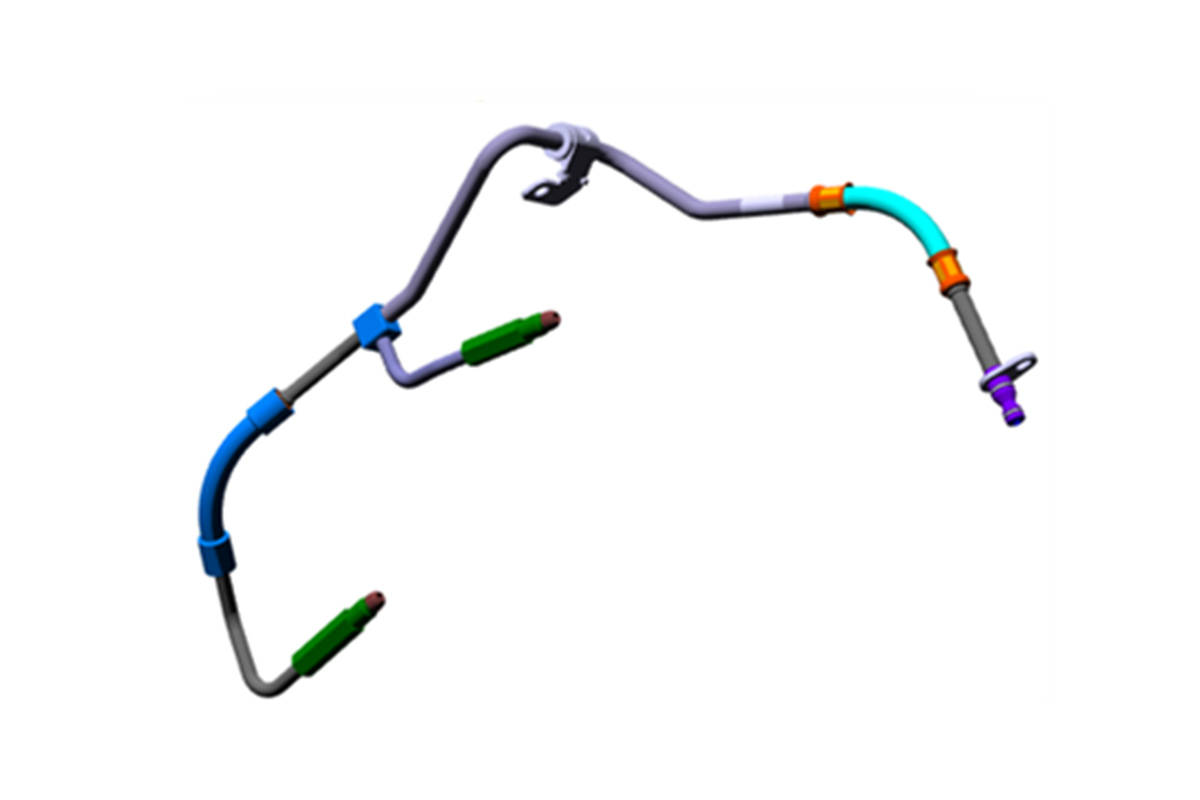

Cooling-system

Degassing-system

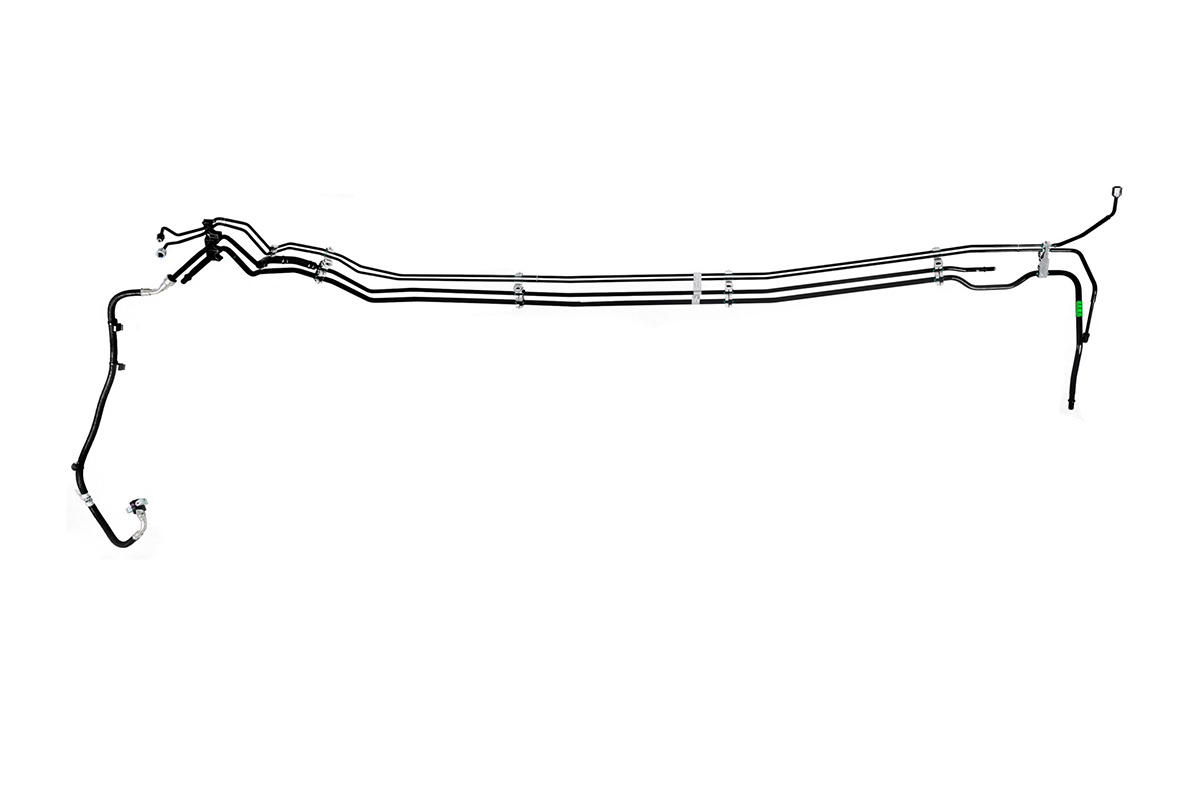

FTS and FBD

Fluid Transfer System and Fuel & Brake Delivery Systems

The FTS-business is amongst the TOP 7 suppliers in the European automotive market and used for thermal management to regulate the vehicles‘ driveline temperature and to transport liquids or air in the vacuum & emissions systems. Seven Indian locations supply sealing solutions and FBD systems for the automotive industry.

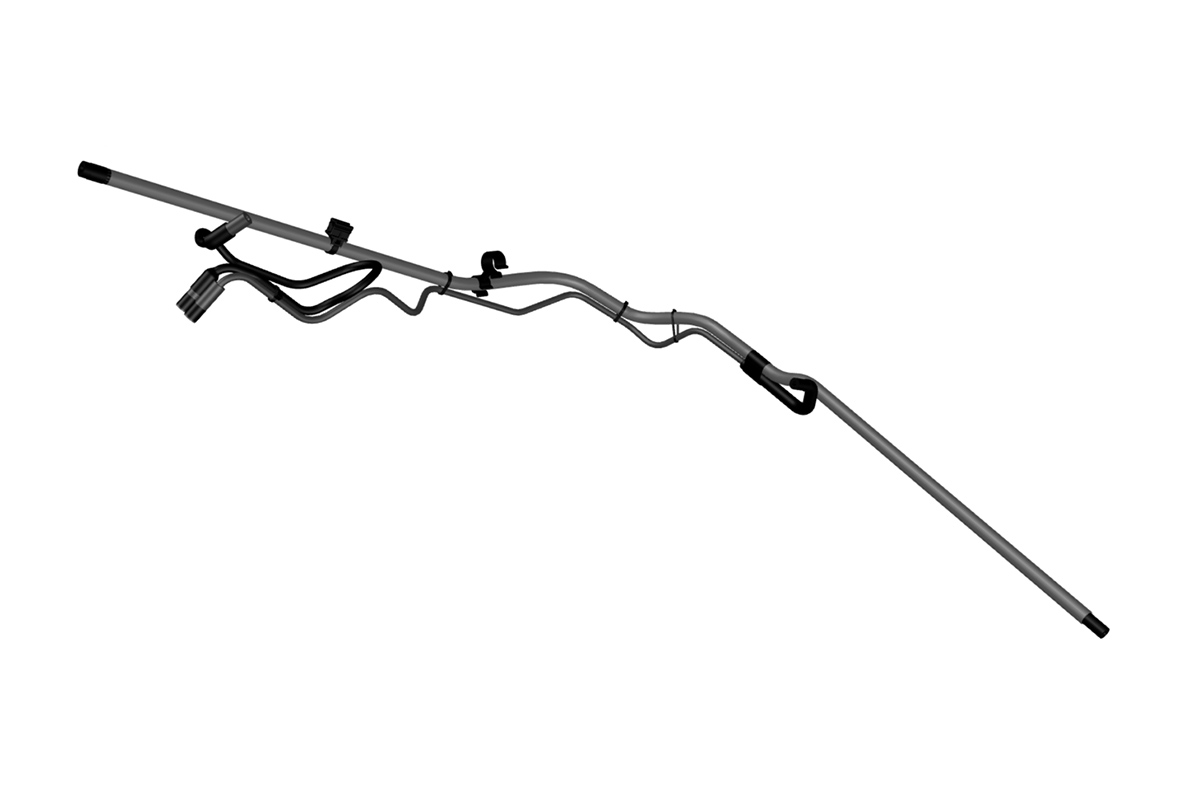

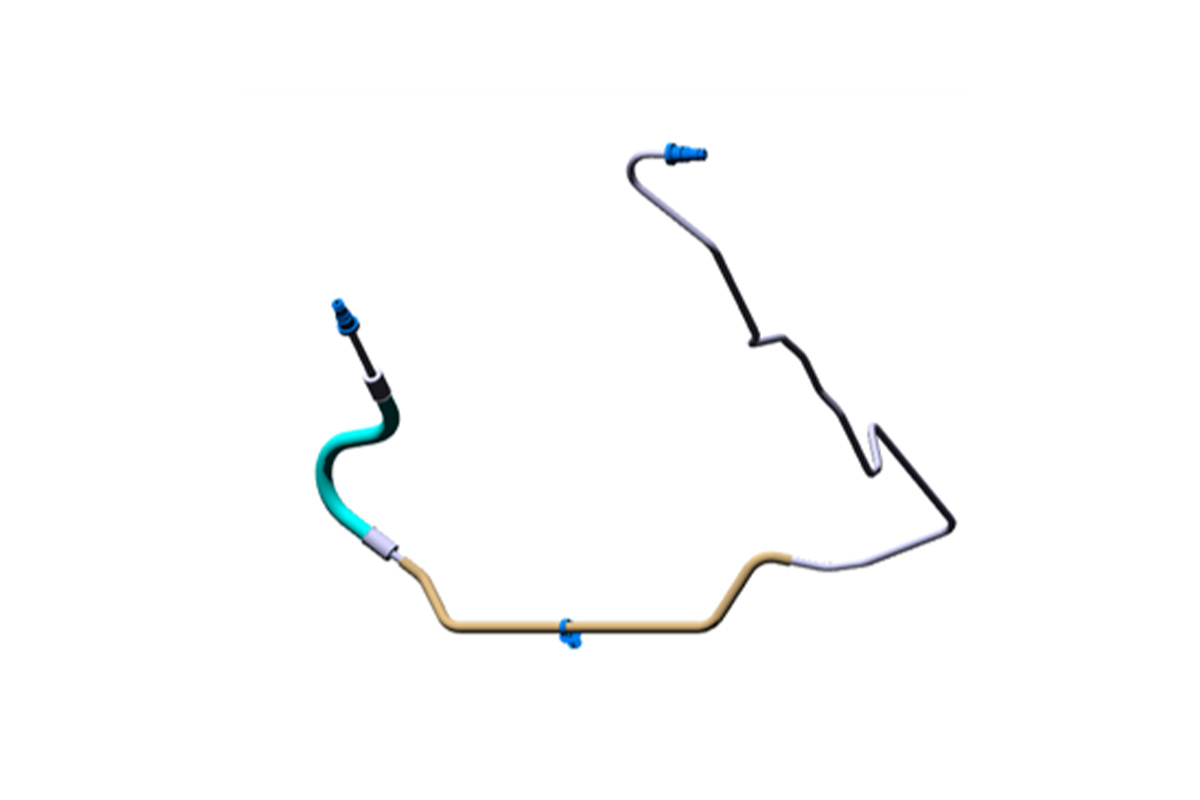

Thermal Management (Glycol lines)

Glycol-lines are Cooling engine turbo transmission oil through glycol thermal fluid, optimizing engine longevity and passenger cabin comfort

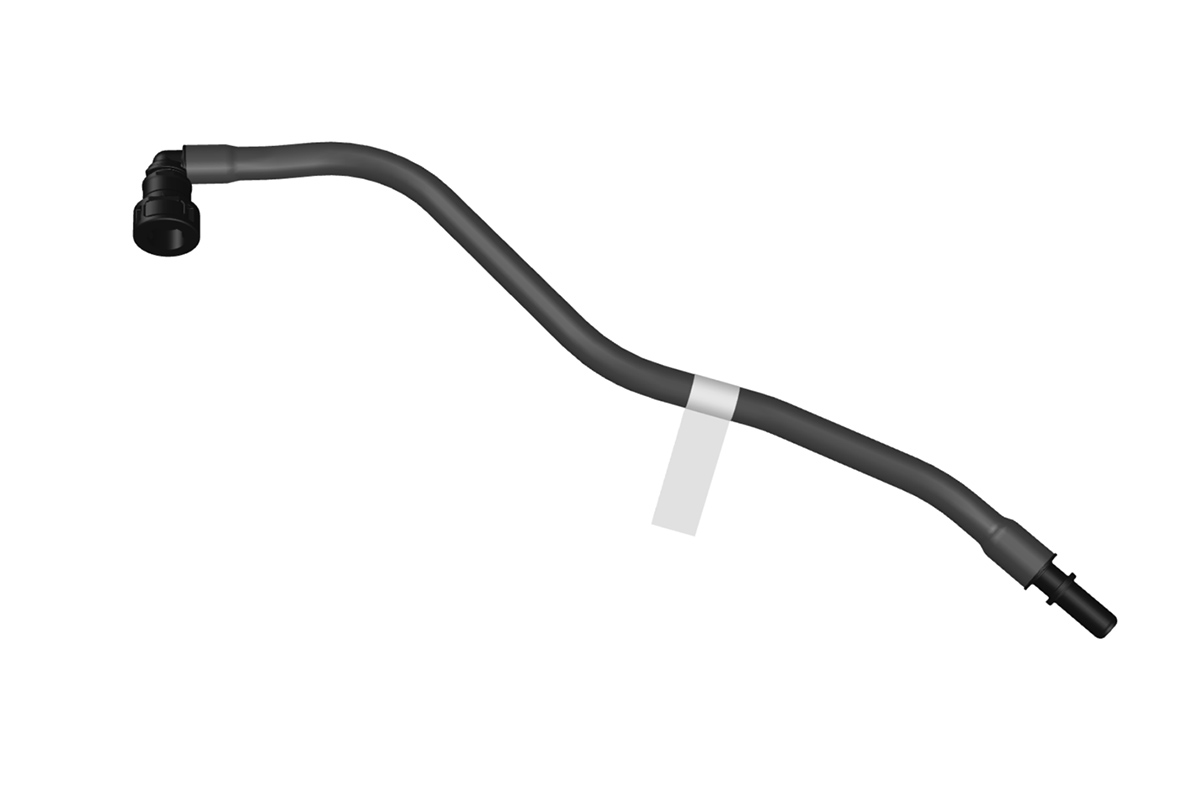

Vacuum & Emission (Air-lines)

Air-lines allow engine breathing, vacuum valve actuation, pressure reduction in crankcase, avoid oil condensation and pressure increase before and after catalyser

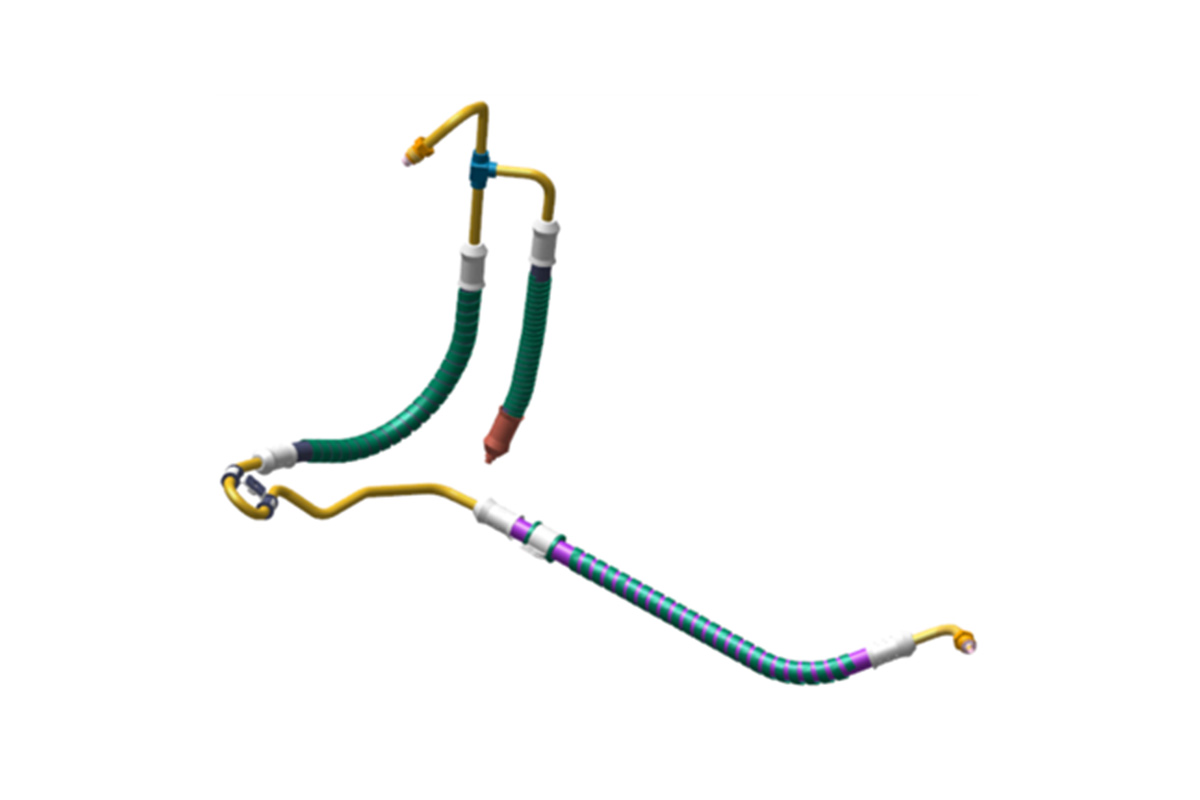

Fluid specialty

Fluid specialty lines have mainly five functionalities: 1/ allowing the fill of urea tank including venting system, 2/ collect and eliminate water around the sunroof, 3/ deliver fuel from tank to engine, 4/ deliver high pressure braking oil through the hydraulic braking system, 5/ cool the engine and transmission oil through an air-oil exchanger.

Compound

Rubber compound production

The rubber compound production consists of two compound-mixing lines, allowing us to produce 180 different compound recipes.

We transform raw materials (polymers, carbon black, process oils and more) into dense and sponge compounds through the mixing process, which takes place inside our Banbury mixers. We produce many different types of compounds, each one with their specific recipe, studied to obtain satisfying mechanical and aesthetical performances.

These compounds are used for internal sealing production and are also sold to third parties. Our main production (93%) is the EPDM-compound with two different vulcanisation systems: Sulphur and Peroxide. Further polymers are: CR (Polychloroprene), AEM (Ethylene Acrylic VAMAC), NR5NBR (Polyisoprene), SBR (Styrene Butadiene), as well as individually composed customer receipts. The spectrum of the final applications is very wide. In general, it is the design of the final application that defines the kind of elastomer our customer uses. Therefore, we have the skill to “sew” the compound into our customer’s vulcanization process.

If you are interested in compounds, please get in contact with us. Compounds are delivered in carton-boxes for a minimum order-quantity of 200 kg.

Physical properties

| Polyisoprene | Styrene Butadiene | Ethylene Propylene Diene Monomer | Polychloroprene | Acrylonitrile Butadiene | Ethylene Acrylic VAMAC | |

| SPECIFIC GRAVITY | 1,0 to 1,2 | 1,0 to 1,2 | 1,0 to 1,4 | 1,0 to 1,4 | 1,0 to 1,30 | 1,0 to 1,30 |

| HARDNESS, RANGE (ShA) | 40-90 | 40-90 | 40-90 | 40-90 | 40-90 | 50-80 |

| TENSILE STRENGTH | ● | ◑ | ◕ | ◕ | ◕ | ◑ |

| ELONGATION | ◕-● | ◑ | ◑ | ◑ | ◑ | ◑ |

| COMPRESSION SET | ◑ | ◑ | ◑ | ◔ -◑ | ◑ | ◑ |

| HEAT RESISTANCE | ◔ | ◔ -◑ | ◕-● | ◑ | ◔ -◑ | ◕ |

| RESILIENCE OR REBOUND | ● | ◔ -◑ | ◑ | ◑–◕ | ◔ -◑ | ○ |

| ABRASION RESISTANCE | ● | ◑-● | ◑-● | ◑-● | ◑-● | ◔ |

| TEAR RESISTANCE | ● | ◔ -◑ | ◔ -◑ | ◔ -◑ | ◔ -◑ | ◔ |

| CUT GROWTH | ● | ◑ | ◑ | ◑ | ◑ | ◔ –○ |

| FLAME RESISTANCE | ○ | ○ | ◔ | ◕ | ○ | ○ |

| IMPERMEABILITY, GAS | ◔ | ◔ | ◔-◑ | ◔ -◑ | ◑ | ◑ |

| WEATHERING RESISTANCE | ○-◔ | ◔-◑ | ● | ◕-◑ | F-◑ | ◕ |

| LOW TEMPERATURE LIMIT (°C) | -40 | -40 | -45 | -40 | -40 | -40 |

| HIGH TEMPERATURE LIMIT (°C) | +80 | +80 | +135 | +100 | +110 | +175 |

| CHEMICAL RESISTANCE PROPERTIES | ||||||

| ACID | ◔ -◑ | ◔ -◑ | ◑ | ◑ | ◑ | ◑ |

| ALKALI | ◔ | ◔ | ◕ | ● | ◕ | ◑ |

| ALIPHATIC HYDROCARBON SOLVENTS | ○ | ○ | ○ | ◑ | ● | ○ |

| AROMATIC HYDROCARBON SOLVENTS | ○ | ○ | ○ | ○-◔ | ◔ -◑ | ○ |

| OIL & GASOLINE | ○ | ○ | ○ | ◔-◑ | ◑-● | ◔ –◯ |

KEY:

○ poor

◔ Fair

◑ Good

◕ Very good

● Excellent

Solutions

Flexible tailored to your needs